1979

The 17th Annual Antique Tractor & Steam Engine Show was held July 26-29, 1979 at the Will County Fairgrounds in Peotone, IL.

COVER

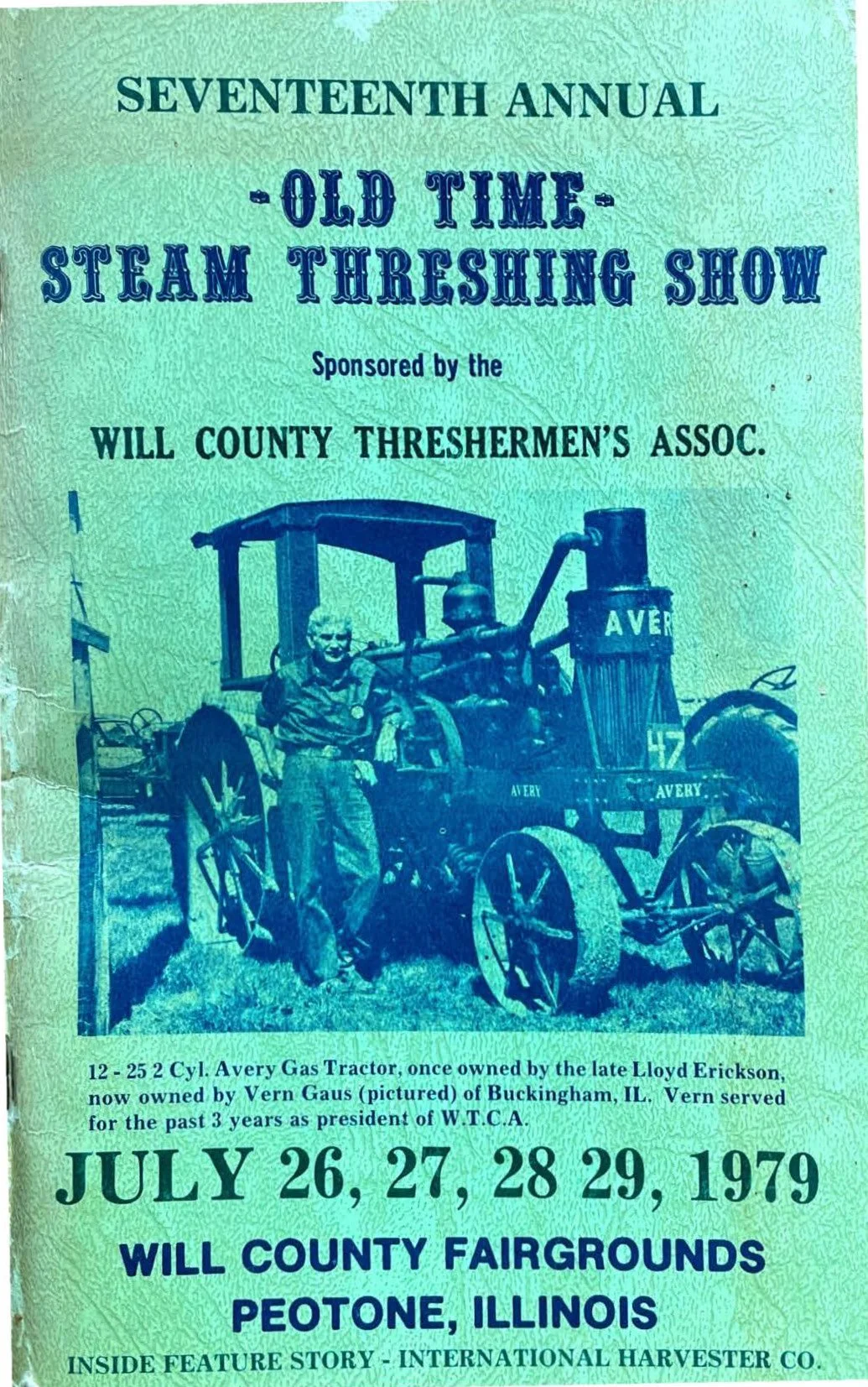

SEVENTEENTEH ANNUAL

·OLD TIME·

STEAM THRESHING SHOW

Sponsored by the Will County Threshermen’s Assoc.

12-25 2 Cyl. Avery Gas Tractor, once owned by the late Lloyd Erickson, now owned by Vern Gaus (pictured) of Buckingham, IL. Vern served for the past 3 years as president of W.T.C.A.

JULY 26, 27, 28, 29, 1979

Will County Fairgrounds Peotone, Illinois

INSIDE FEATURE STORY - INTERNATIONAL HARVESTER CO.

TITLE PAGE

17th ANNUAL STEAM ENGINE SHOW

WILL COUNTY THRESHERMEN'S ASSOCIATION

FOUR DAY CELEBRATION

JULY 26, 27, 28 & 29, 1979

WILL COUNTY FAIRGROUNDS, PEOTONE, ILLINOIS

Daily Parade at 2:00 P.M.

22 H.P. ADVANCE RUMELY OWNED BY NORM CHRISTIANSEN, PEOTONE, ILLINOIS

EXHIBITION ANTIQUE TRACTOR PULL DAILY ANTIQUE MARKET DAILY - SMALL ANTIQUES SOLD HAND CRAFT EXHIBITS

HORSE DRAWN WAGONS - HAYRACK RIDES FOR KIDDIES - MEALS & SHORT ORDERS SERVED ON GROUNDS

Free Parking - Lots of Shade - Seating - Rest Rooms

ABOUT

OFFICERS

WILL COUNTY THRESHERMEN'S ASSOCIATION

NORMAN CHRISTIANSEN, Peotone, Illinois, President

KEN KESTEL, Vice-President, Manhattan, Illinois

RUSSELL HOSSBACH Joliet, Illinois, Secretary

DICK BORMS, Treasurer

DIRECTORS

ALAN CHRISTIANSEN, Manhattan, Ill.

LARRY CHRISTIANSEN, Peotone, Ill.

LEONARD DELANEY, Manhattan, Ill.

GARY FELLOWS, Manhattan, Ill.

GORDON FERGUSON, Morris, Ill.

STANTON GAST, Manhattan, Ill.

CHARLES GAUS, Buckingham, Ill.

DAVE KARL, Rockdale, Ill.

RAY KESTEL, Manhattan, Ill.

ART LOOTEN, West Chicago, Ill.

JIM LOOTEN, West Chicago, Ill.

JOE MURPHY, Manhattan, Ill.

MEL MYERS, Chicago Heights, Ill.

PAT NEINER, Manteno, Ill.

ROBERT NEINER, Manteno, Ill.

HARLOW NICHOLSON, Elwood, Ill.

LARR¥ PONTON, Peotone, Ill.

DAVE ROWLEY, Lockport, Ill.

FRED WILHELMI , Joliet, Ill.

JIM JECHA, Mokena, Ill.

PROGRAM SCHEDULE OF EVENTS

* 8:00 A.M. Gates Open

* 10:00 A.M. Activities Begin (threshing, sawing, fans, shelling, well drilling, etc.)

* 12:00 Noon Noon Whistles (lunch)

* 12:45 P.M. Activities Resume

* 1:30 P.M. Line Up for Parade

* 2:00 P.M. Parade of All Equipment (grandstand)

* 3:00 P.M. Tractor Pull Also: threshing, sawing, etc.

* 5:00 P.M. Days End

*SPECIALS*

Saturday July 29, Open till Dark

* Saturday - 6:00 p.m. - Tractor Pull & all other activities

*Saturday - 7:00 p.m. - Parade

2nd Annual "Summer Arts & Crafts Daze"

Saturday July 28 - 10 a.m. - 8:00 p.m.

Sunday July 29 - 10 a.m. - 5 p.m.

In the Atrium

THE LADIES PAGE (RECEIPES)

APPLE SLICES

3 lbs. tart cooking apples, pared and cut into eights.

1 cup water

1 teaspoon cinnamon

1/4 teaspoon salt

1 1/4 cups sugar

2 Tablespoon cornstarch

1/4 cup water

CRUST -

2 cups flour

1/2 teaspoon baking powder

1/2 teaspoon salt

3/4 cup lard or shortening

1 teaspoon lemon juice

2 egg yolks, beaten.

½ cup water

Bring water, sugar cinnamon, and salt to boiling point. Add apples and cook slowly for ten minutes. Blend cornstarch with the cup water and stir into hot mixture. Cook 5 minutes longer, stirring gently.

Cut the lard into the sifted flour, baking powder and salt as for pie crust. Mix lemon juice, egg yolks and water. Sprinkle over flour mixture. Blend it lightly. Divide in to two parts. Roll the first piece to fit bottom and sides of shallow pan about 9 x 13 inch. Fill with apple mixture. Roll rest of dough to fit top, seal edges. Cut a design for steam vents. Bake 450° for 20 minutes, reduce to 350° bake 30 minutes more.

ORANGE - PINEAPPLE SALAD

1 #2 can crushed pineapple.

½ package miniature marshmallows

3 oz. package of cream cheese

2 packages orange-pineapple gelatin

1 tablespoon salad dressing

1 large can Pet milk

½ cup finely chopped nuts.

Heat ½ can crushed pineapple and marshmallows until marshmallows melt. Remove from stove, stir in cream cheese and one package dry gelatin, add salad dressing set aside to cool for at least ½ hour. Whip chilled milk, add to cooled mixture with rest of pineapple and nuts.

Pour into a large serving dish (9 x 13) chill until set. Cover with a package of gelatin made by regular recipe and cool until syrupy. Chill until firm. Makes 12 servings.

BAKED SALMON CASSEROLE

1 can cream of celery, or 1 can cream of mushroom soup.

½ cup mayonnaise

1/4 cup shredded cheese

a Iittle onion

1 can (7 3/4 oz.) flaked salmon.

1 10 oz. package frozen peas

1 4 oz package noodles - cooked and drained

Mix soup, mayonnaise, cheese, and onion together. Add peas, noodles, and salmon. Place in casserole dish and bake for 1 hour at 350° degrees.

LETTER FROM THE PRESIDENT:

The Will County Threshermen's Association welcomes you to Seventeenth annual show. It is the club's sincere hope that you enjoy our show and will tell all of your friends to attend so our seventeenth show will be a huge success.

There is much planning and hard work for everyone in the organization to prepare for a show of this size. While not intending to take anything away from anyone, I particularly want to mention two very fine and hard-working gentlemen. These two men are at the sawmill, namely Joseph Murphy and Stanton Gast. In my opinion they have the hardest and dirtiest job at our show. The handling of the large logs and the saw dust blowing around are some of the obstacles with which they must contend. I click my heels and salute these two fine gentlemen.

A big thank you to all the women of the organization. You are doing an incredible job. Every year your receipts are growing. Keep up the good work. It is greatly appreciated by everyone.

Many of the shows last year were very hard hit by the inclement weather. It takes over ten thousand dollars to promote a satisfactory show. We sincerely hope all of you that were rained out will come back strong this year. The best of luck from this organization.

It is always a pleasure to hear or read a favorable comment. Mr. James B. Cain of Dolton, Illinois, wrote a lengthy article in the ENGINEERS AND ENGINES magazine's January and February issues and had the following to say about the Will County Threshermen's Association show: "My third visit, second at this location. Another of Illinois' fine shows, well staged and well-handled." Thank you, Mr. Cain, for those very encouraging words. Our organization must be doing something right. Past President, Ray Kestel's trademark of the show is activity. Something doing on all of the time. We start at 10:00 a.m. and close at 5:00 p.m., except Saturday when we close at dusk.

All equipment at this show is individually owned except the sawmill, and the large fan. Last year I was given a medium-sized fan which was badly in need of restoring. After considerable work and some expense, James Watters and I have this fan in presentable condition. It can be seen at the model engine exhibit. When not shelling corn or sawing wood on the buzz saw, my engine will be operating this fan.

Take time to see all of our show, including the large flea market. Hope we have done a good job of entertaining you so we can expect a visit from you again next year. Many thanks from all of us.

Joseph A. Baleria

MEMBERS IN MEMORIUM

HERMAN CHRISTIANSEN, Manhattan, ILL.

MRS. HERMAN CHRISTIANSEN, Manhattan, ILL.

JOHN J. BRODESKE, Joliet, ILL.

PAUL AUDETTE, Manhattan, ILL.

WM. A. ILINKINGER, Peotone, ILL.

HAROL-0 FRIDDLE, Elwood, ILL.

NICK DONEDAL, Zion, ILL.

CHAS. ERICKSON, DuPage Township

FRANCIS GALLAGER, Peotone, ILL.

WILLARD HAFKA, New Lenox, ILL.

WALT PALMER, New Lenox, ILL.

CORRINE KESTEL, Manhattan, ILL.

FRANK KLEMME, Crete, ILL.

JERRY HEITMAN, Manhattan, ILL.

E.O. HERMAN, Peotone, ILL.

GEORGE MOORE, New Lenox, ILL.

LOUISE KESTEL, New Lenox, ILL.

TRUMAN KOOPMAN, Flangan, ILL.

JOE SCOTT, New Lenox, ILL.

IRWIN KIRSTEIN, Manhattan, ILL.

LEO MURPHY, Elwood, ILL.

HAROLD SWANBERG, New Lenox, ILL.

GLEN ALBRIGH, Hersher, ILL.

LLOYD ERICKSON, Elwood, ILL.

ROBERT McHUGH, Minooka, ILL.

HARRY KIRSTEIN, Manhattan, ILL.

CHESTER KIRSTEIN, Manhattan, ILL.

GERALD NORCROSS, Elwood, ILL.

CHET BROWN, Elwood, ILL.

BERNARD PEARSON, Harvey, ILL.

LES BARTON, Elwood, ILL.

LES DIEDRICH, Lombard, ILL.

HENRY LINDEMAN, Peotone, ILL.

ARMAND PONTON, Bradley, ILL.

FRANK LANDORF

CLARENCE LANDORF, Naperville, ILL.

FRANCIS DELANEY, Manhattan, ILL.

ILLIAM BROWN, Morris, ILL.

HARLOW LARSON, Gardner, ILL.

KEITH HOSSACK, New Lenox, ILL.

IMAGE CAPTIONS:

MODEL "T" OWNED BY FRED WILHELMI, JOLIET, ILLINOIS AT THE WHEEL

15-30 RUMELY OIL-PULL & 28" AVERY THRESHING MACHINE BOTH OWNED BY MEL MEYERS, CHICAGO HEIGHTS, ILLINOIS (PICTURED STANDING)

28-50 H.P. 4 CYLINDER HART-PARR, OWNED BY FRANKLIN WEBER, MANTENO, ILLJNOIS

15-30 McCORMICK-DEERJNG "KEROSENE BURNER" OWNED BY RAY AND KEN KESTEL

65H.P. BAKER STEAMER OWNED BY FAY ORR, MOMENCE, ILLINOIS

TOM RUNTY TAKES ON SOME COAL, TOM IS ENGINEER ON 18 H.P. AVERY

2 FARMALLS (F 14 and F 12) BOTH OWNED BY DICK BORMS, PEOTONE

INTERNATIONAL TD-40 OWNED BY VERLE JOHNSON, MARSAILES, ILLINOIS

SILVER KING AND CULTIVATOR OWNED BY VERN GAUS, BUCKINGHAM, ILLINOIS

LINE UP OF 3 ENGINES LOOTEN'S MINNEAPOLIS, AKERMEN'S NICHOLS & SHEPARD, AND NEINER 'S CASE

1935 FORDSON OWNED BY LA VERNE HUNT, ST. ANNE

18 H.P. UNDERSLUNGAVERY OWNED BY NORM CHRISTIANSEN & SONS, PEOTONE, IL

BEAUTIFUL SILVER-KING OWNER: VERN GAUS, BUCKINGHAM, ILLINOIS

JOHN-DEERE “D” OWNED BY DEAN BETTENHAUSEN, OF TINLEY PARK, ILLINOIS

22” McCORMICK-DEERING OWNED BY ART AND JIM LOOTENS, WEST CHICAGO, IL

30-60 SQUARE RADIATOR AULTMAN-TAYLOR OWNED BY FAY-ORR, MOMENCE, ILLINOIS

PAUL'S NICHOLS BELTED TO HUGE FAN AT SHOW

KESTEL'S KECK (ON LEFT) AND PONTON'S KECK ON THE RIGHT - HEAD OFF AND ARE READY TO DO BATTLE

INTERNATIONAL TRUCK OWNED BY HARLOW NICHOLSON, ELWOOD, IL. PAST VICE-PRESIDENT OF W. C.T.A.

22 H.P. ADVANCE RUMELY STEAMER OWNED BY NORM CHRISTIANSEN & SONS, PEOTONE, ILLINOIS

MEL MEYERS BELTED TO HIS THRESHER

"LIGHT- FOUR" HUBER, OWNED BY RAY KESTEL, MANHATTAN, ILLINOIS

CHRISTIANSEN POWER EQUIPMENT 4 HORSE HITCH AND STAGECOACH

18 H.P. NICHOLS & SHEPARD OWNED BY PAUL AKERMAN, NAPERVILLE, ILLINOIS

1929 KECK-GONNERMAN STEAMER 19-65 H.P. OWNED BY KEN, MADONNA, & MELISSA KESTEL, MANHATTAN

MEL MEYERS "OUTFIT" IN OPERATION, HARLOW NICHOLSON GOES ALONG FOR THE RIDE!

22 H.P. ADVANCE RUMELY STEAMER, OWNED BY NORM CHRISTIANSEN, STANDING, PRESIDENT WCTA.

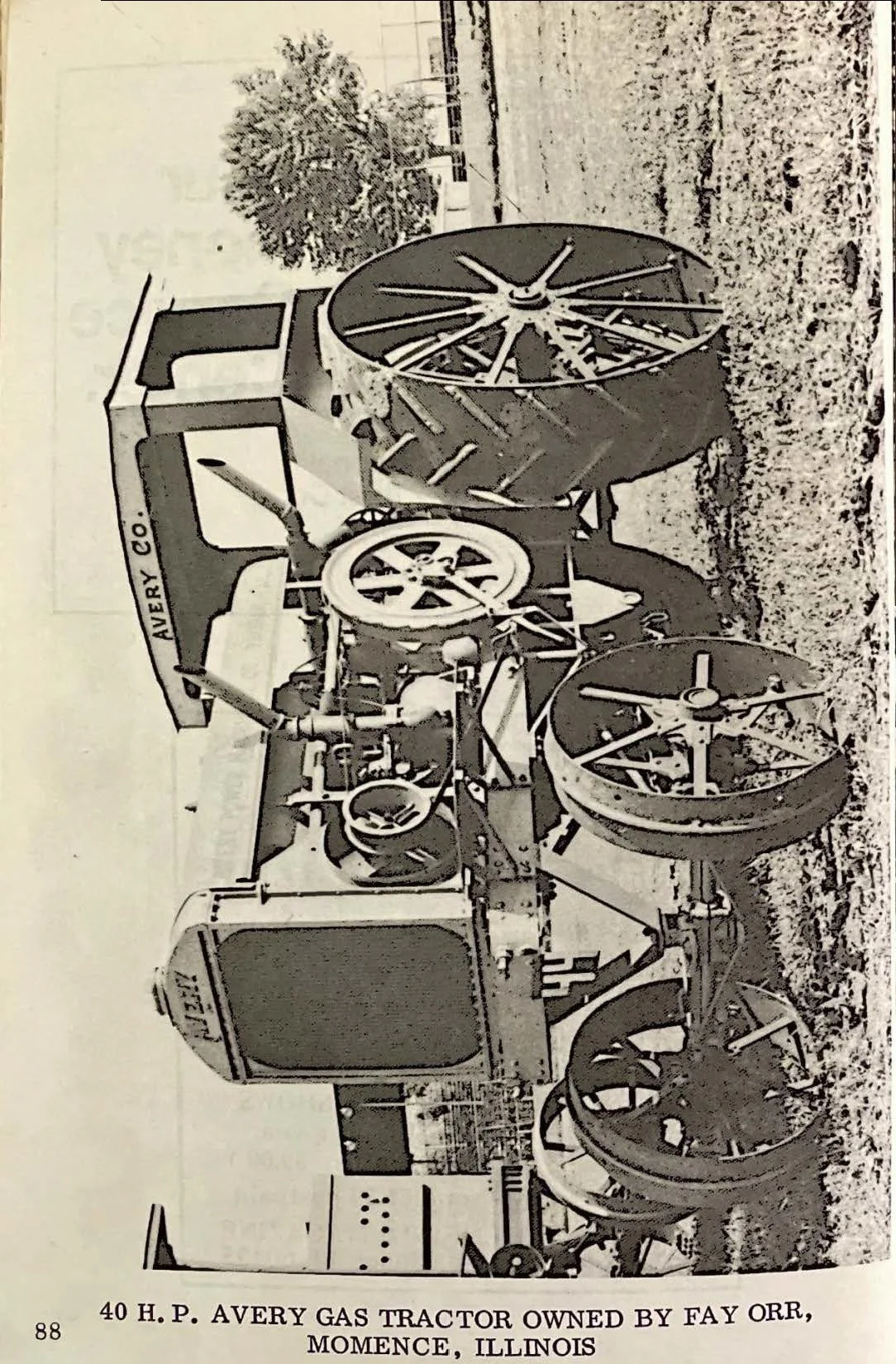

40 H.P. AVERY GAS TRACTOR OWNED BY FAY ORR, MOMENCE, ILLINOIS

FARMALL F-12 OWNED BY DICK BORMS, PEOTONE

1945 101 JUNIOR MASSEY-HARRIS OWNED BY LA VERNE HUNT, ST. ANNE, ILLINOIS

BOB NEINER, MANTENO, ON HIS 65 H. P. CASE

MEMBERS BAILING STRAW FROM SEPERATOR. ANYONE HAVE A MATCH?

History and Development of INTERNATIONAL HARVESTER

The Reaper

A Spur to Progress

The invention of the reaper, as much as any other single factor, was responsible for the conversion of the United States from an almost purely agrarian nation in 1830 to its present position as the world's greatest industrial power. By releasing manpower from the soil to be deployed into other channels of activity. Cyrus Hall McCormick applied a spur to an industrial revolution in America that led to the greatest era of invention and mechanical progress the world had ever known.

In order to understand fully the implication of the reaper, it is necessary to examine briefly the conditions under which the farmer of 1830 operated. Then, as now, the search for food was man's first consideration. Until that search was successful, he had no time for any other activity. Only after he had produced enough food to satisfy his hunger could he devote time to other occupations. In the centuries preceding 1831, 95 percent of the population of the world was forced by the need for food and shelter to work on the land.

Until the invention of the reaper, advances in farming methods were so slow as to be almost imperceptible. In spite of its status as humanities basic industry, agriculture failed to progress or even to undergo much study in ancient times. It was still a laborious, unrewarding pursuit in 1830-one offering little promise of leisure or security to anyone engaged in it. The farmer was completely at the mercy of the soil and the elements. If circumstances caused him to fail to produce, he and his fellow men were confronted with the specter of famine. It was an economy of scarcity, a world in which the overwhelming majority of the population toiled unceasingly to supply its merely physical needs.

Of all the problems of the farmer, the harvesting- of grain was the most stubborn, having throughout history resisted every effort to apply any but human power to its solution. Horses and oxen had been used to pull plows, harrows, and carts but were of no avail at harvest time, when only countless hours of backbreaking toil could cut and bind the grain before it rotted on the ground. Since there were usually no more than ten days in which to harvest, the least delay caused by the weather, or a lack of manpower made for a loss of at least part of the crop. At best, this created shortages and uncertainty; in extreme cases it would result in actual famine.

The principal implement of the harvest in the earliest recorded days of history was the sickle. a curved knife with which a strong man could cut a half-acre in the course of a day. In 1830, the sickle was still in general use under certain crop conditions. Wielding a sickle is grueling labor; each bunch of grain must be grasped in one hand and cut by a sweep of the blade.

The scythe, practical only for cutting standing grain, was introduced sometime in antiquity, and made it possible for a man to cut two acres a day. During the eighteenth century, the scythe was improved by the addition of wooden fingers. With this implement, called a “cradle” grain could be cut and at the same time gathered and thrown into swaths, making it simpler for others following to bind it into sheaves.

The first reaper started the transition to the highly mechanized farming of today and at the same time opened the door to other improvements, proving to the world that long hours of drudgery were not necessary to supply its population with food. After the reaper had solved the problem of the grain harvest, new uses for animal power on the farm were discovered. Since that time there has been no hunger in the United States brought on by man's inability to produce sufficient food. The only scarcity has been the result of fault in our distributive system. It seemed that civilization had been accustomed to scarcity for so many centuries that it occasionally found abundance too strange a phenomenon to cope with effectively.

Almost as far-reaching as the removal of the threat of famine from this country was the trend started by the reaper toward releasing men from the farm. In 1830, 91 percent of our nation's population of 12.9 million lived on farms. After the introduction of the reaper, the population started flowing steadily to urban areas. permitting the development of vital industries. By 1975, 95 percent of the 200 million Americans were living in cities and small towns, with only 5 percent living on farms.

-With the earliest known harvesting implement, the sickle, or reaping hook, one man could cut from one-half to one acre in a day.-

Mechanization and other technological advances have improved the efficiency of the American farmer to the point where he now produces enough for himself and 45 others. One hundred and forty-five years ago he produced only enough for himself and three others.

The invention of the steam engine by James Wan in the latter part of the eighteenth century is generally credited with beginning the Industrial Revolution in England. By providing man for the first time with a source of power other than that which he derived from his own efforts or that of domestic animals, the steam engine made possible modem transportation and industrial power. However, it is significant that its benefits were not completely realized until Cyrus Hall McCormick provided a means of releasing manpower to operate steamboats, railroads, and factories. Not until man had time to turn from the unceasing task of satisfying his hunger could our industrial system reach its fullest flower.

-With the scythe, companion tool to the sickle, one man could cut up to three acres of grain a day.-

The reaper, working hand in hand with new methods of steam transportation, was one of the prime factors in the rapid westward movement of our civilization. As pioneers pushed to the West at the rate of 40 miles a year, farmers aided by new machinery, were putting land into productive use as fast as it was won. The various new inventions had a tendency to be mutually dependent. There would have been fewer railroads if farms had not produced more for them to carry and released men to help build and run them. At the same time, the rapid extension of land put under cultivation was assisted by the railroads, which were able to deliver the produce of the farm almost as rapidly as it was harvested. Each did its part in breaking the bottleneck between the vast, fertile areas of the West and the people in the East waiting to be fed.

-Production increased when the “cradle” was added to the scythe. Its four wooden fingers caught the cut grain so the farmer could throw it into a swath, ready to be bound into sheaves.-

The achievement of farm equipment in supplying men and food to industry is matched by what it has dome for the farmer himself, since it fulfilled the purpose of all labor-saving machinery – to enable men to produce more and more with less and less effort. The first reaper could harvest as much grain as 30 men with sickles or five with cradles, and opened man’s eyes to the possibilities of leisure by making it possible for him to obtain the necessities of life without expending every last ounce of energy. Every subsequent improvement in farm equipment has raised his standard of living by increasing the yield from land and decreasing the amount of time that must be spent on it.

-The reaper, with its two-man crew, could cut as much grain daily as 5 men with cradles or 20 men with sickles, thus releasing extra hands for binding and stacking the cut grain.-

Development of Farm Machinery after the Invention of the Reaper

The introduction of the reaper ushered in an extraordinarily productive era of invention in all lines of farm equipment. Stimulated by the impressive success of McCormick’s machine, other inventors attacked the problems of the farmer with equal vigor. During the period between 1830 and 1850, every phase of agriculture underwent rapid development. The steel plow, which made it possible for the first time to tum the rich, sticky soil of the prairies, was introduced to replace the inefficient wood and cast-iron implements that had been used for centuries. In 1834, the tint threshing machine appeared, doing away with the laborious custom of flailing grain from chaff. Hand sowing of seed started to become obsolete when the grain drill, which permitted rapid, accurate planting, was invented. Harrows and cultivators in vastly improved form were developed - to be eagerly accepted by the pioneers who were opening the great American West.

All these new machines were designed to utilize animal power to the fullest possible extent and make it forever unnecessary for the farmer to engage in ceaseless backbreaking toil simply to earn a bare subsistence. Between 1830 and 1840, the time required to harvest an acre of wheat was reduced from about 37 hours to an estimated 11 1/2 hours, with an even greater decrease in the amount of physical labor demanded of the farmer. Such developments had a profound effect upon the fanner's way of life: he could now look forward to the prospect of greater security, profits, and leisure for himself and his family. Moreover, the faster he was able to acquire mechanical aids, the more land he could put into productive use. This had the tendency to uproot him, make him spread out toward the West, where millions of acres of fertile land waited to be put under cultivation. He became one of the driving forces behind the nation’s rapid expansion and development.

By 1846 the acceptance of the reaper in the great farming areas of the Middle West was complete enough to justify the building of a factory to manufacture reapers in quantity. Cyrus HalI McCormick moved his business to Chicago, the logical shipping center of the new grain territory. His first factory was established on the north bank of the Chicago River near Lake Michigan, becoming one of the first of Chicago’s pioneer industries. As his original contracts with outside manufacturers expired, McCormick refused to renew them, preferring, once he had the facilities, to have all his machines built under his personal supervision.

During this period, while McCormick was concentrating on the production of his reaper, he was also developing methods of selling advertising and distributing it. Upon the expiration of his original patents, which in spite of litigation were nor renewed, he met a sudden increase in competition simply by outselling his rivals and sending his agents throughout the United States - even to the more remote sectors - to convince farmers of the merits of his reaper.

The interests of the farmer were always uppermost in McCormick's mind. Leaving the manufacturing details of his business in the hands of his brothers, he spent most of his time designing and testing improvements on his machine and, during the harvest season, studying the reaper in operation. Trips to the harvest areas each year enabled him to keep in close touch with the problems of the farmers and to learn their views on possible improvements. The most popular method of advertising and selling in those days was to stage contests with competing manufacturers before the farmers themselves. McCormick supervised many of these field trials himself, keeping a watchful eye for weaknesses in the performance of his reaper. Because of his insistence upon the highest possible standards of quality and workmanship, McCormick’s machines usually came out ahead in such contests. He had, however, the courage and integrity to recognize flaws in his machine and never hesitated to accept advice he considered sound.

The first major improvement in the reaper was adopted in 1852, when a self-rake device was added to sweep the grain from the platform. Through this mov, the man who cleared the platform with a hand rake was released to other work. A further change resulted from prolonged experimentation by the Marsh brothers of DeKalb, Illinois, which culminated in 1858 in the Marsh harvester, an idea whose worth was quickly recognized by McCormick and applied to his reaper. This machine employed continuous canvas aprons to raise the grain to a table, where two men riding on the reaper could bind it as fast as it collected and throw the bundles over the side. When, in 1871, McCormick began production of a wire binder, hand labor was virtually eliminated from the process of harvesting. During the next decade, wire binders were manufactured in large quantities but were never accepted as entirely satisfactory by the farmers, who claimed that the wire injured their livestock.

The wire binder’s brief day of supremacy ended with the invention of the twine binder, finally perfected by John F. Appleby of Wisconsin in 1879. McCormick, realizing its value almost immediately as an adaptation to his own machine, procured the rights to manufacture the twine binder and commenced to produce it in quantity. Soon the Appleby binding attachment, mounted on the Marsh type harvester, was being manufactured by nearly all the harvesting machine manufacturers in the country. These machines, in spite of small variations in detail, were based on the frame and reciprocal knife cutting mechanism of McCormick's original reaper. Subsequent binders essentially were refined versions of the same machine.

The harvesting machinery business first began to assume its worldwide character in 1851, when McCormick entered his reaper in the exhibition of industries of all nations at the Crystal Palace in London. There, the reaper performed so efficiently in a series of field tests under all conditions that it received the highest award of the fair, the Council Medal. English writers, at first inclined to scoff at the new machine, finally were forced to admit that the McCormick reaper alone was worth more to England than most of the entire exhibition. The spectacular success of this experience led McCormick to make arrangements with a British firm to manufacture his reaper. Throughout the next decade, the use of the reaper spread rapidly through all Europe. McCormick had tapped a great potential market.

Formation of International Harvester Company

During the latter part of the nineteenth century, the farm equipment industry, influenced by the rapid expansion of agriculture for which it was so largely responsible, grew into one of the most highly competitive businesses in America. This period of severe competition had a restricting effect: so many companies entered this market that no single enterprise could muster enough capital to engage in normal development or expansion. At one time, it was estimated, more than 2,000 concerns were manufacturing one or more lines of equipment. Most were barely able to keep abreast of the times - much less anticipate the farmer’s needs. Meanwhile, the foreign market, which had first been opened by Cyrus Hall McCormick in 1851, remained a fertile and virtually untouched field of operations. Few companies had either the capital or the organization necessary to develop a satisfactory export business.

-By 1846, the success of the McCormick reaper justified the building of a factory for quantity production. The plant was located on the north bank of the Chicago River, near Lake Michigan.-

The two leading manufacturers of harvesting machinery at the tum of the century were McCormick's organization and the Deering Harvester Company, also located in Chicago. This company had been founded in 1869 by William Deering, another pioneer in the development and perfection of agricultural implements. ln 1902, the two companies combined with three smaller concerns - the Milwaukee Harvester Company; Warder, Bushnell and Glessner Company; and the Plano Manufacturing Company - to form the International Harvester Company. The prime reasons behind the organization of the new

-For many years after its 1902 formation, International Harvester Company was identified by the “I.H.C.” monogram. Today’s symbol is shown at right.-

company were to develop new products, to bring about a more diversified line, and to give more attention to the foreign market. Cyrus H. McCormick, son of the man who had perfected the reaper and head of the McCormick Harvesting Machine Company at that time, became the first president of the International Harvester Company the day after its formation.

With the exception of the Warder, Bushnell and Glessner plant at Springfield, Ohio; that of the Milwaukee Harvester Company; and a Deering factory at Hamilton, Ontario, all the manufacturing properties acquired by the consolidation were located in or around Chicago. The plant of the Plano Manufacturing Company on Chicago’s south side became the Company’s West Pullman Works. The Company also established its General Offices in Chicago, where they have remained ever since. In addition, the Deering Company, which had reached the forefront in its field largely through its manufacturing sagacity, contributed to the corporation coal, iron, and timber lands and a steel mill in South Chicago, now Wisconsin Steel Works, giving the Company a source of raw materials sufficient to provide for expansion and product diversification.

The effect of the merger upon foreign trade became apparent almost immediately. Spurred on by new capital, new resources, and a larger organization, the Company’s foreign business doubled within five years, and within ten had increased fivefold with the extension of trade, particularly effective in Great Britain, Western and Central Europe, Russia, South America, and Australia. By 1909, factories had been established in several European countries, and sales outlets had been set up in most of the civilized countries of the world. International Harvester Company’s worldwide nature had become firmly established.

All the companies entering into the new corporation were engaged in the manufacture of grain harvesting equipment, binders, hay and corn harvesting machines, and twine, but it was soon realized that the industry’s tradition of service to the farmer and the nation, which had begun with the invention of the reaper, could not be maintained solely by further development of these machines but must include expansion into aII lines agricultural implements and excursions into types of machinery that were then merely in the planning stage.

Ever sensitive to the needs of the farmer, the directors of the new corporation made pians to incorporate into the International Harvester line implements that would serve every purpose of the farm - many of

-HELPING MAN HELP HIMSELF-

which had not even been dreamed of a few years before. It was felt, too, that a more diversified line of products would remove the seasonal character from the harvesting machine business and provide employment on a year-round basis to the thousands of International Harvester factory employees and dealers. The addition of new products would require production at a plant during the periods it was not ordinarily manufacturing harvesting equipment.

The first step in the development of a complete line was the acquisition of the D. M. Osborne Company, at Auburn, New York, which manufactured a line of harvesting and tillage implements designed to meet the eastern trade. Because of its location near the eastern seaboard, the addition of that plant was also in line with the Company’s desire to expand its foreign trade. In 1904, the purchase of the Keystone Company, at Rock Falls, Illinois, added an historic line of tillage and haying tools. This factory, subsequently sold, became known as Rock Falls Works. About this time the Weber Wagon Works of Chicago became an International Harvester property. The Company's line of farm implements became complete with the acquisition in 1918 of steel and chilled plows through the purchase of companies which operated the present Canton Plant at Canton, Illinois, and a plant at Chattanooga, Tennessee, and the addition of a line of seeding machines manufactured at Richmond, Indiana.

During these years the International Harvester Company had been rapidly developing and putting into production new lines at its original plants. By 1912, corn binders, ensilage cutters, seeding machinery, harrows, and manure spreaders had been added to the catalog of implements offered to International Harvester dealers. The pioneer light harvester-thresher was introduced in 1914: the stationary thresher, four years later.

Throughout this period there was a general tendency to simplify the various lines of traditional harvesting machinery inherited by the Company, resulting finally in the Company’s dropping entirely the Champion, Osborne, and Milwaukee lines of harvesters. Later the two remaining lines were merged into one - the McCormick-Deering - with the best features of each pioneer machine retained. Consequently, work was simplified for dealers and the Company’s sales and servicing departments. This change also served to concentrate experimentation and attempts at improvement upon one identifying line of machinery.

The gradual broadening of the Company’s manufacturing field has been in complete accord with Cyrus Hall McCormick’s original desire to anticipate and meet the farmer’s needs. Every new machine developed has been a response to definite needs of agriculture. This has resulted not only in a constant bettering of the farmer's standard of living but has also redounded to the advantage of the International Harvester Company by giving its employees more regular employment and its dealers something to sell at every season of the year.

The Growth of Power Farming

The key to all progress in agriculture is power. As long as there was only human energy-supplemented by the limited use of animal power-to perform the multiple operations required by farming, progress was necessarily slow. When Cyrus Hall McCormick perfected the reaper, he brought to the farmer a broader application of animal power by demonstrating its practical use in the harvest. From that point, farming methods leaped forward to the greatest period of development the world had ever witnessed.

As this development accelerated, however, it became apparent that there were definite limitations to the use of animal power in fanning. Not only was the horse limited in strength and endurance, but it was also expensive to maintain. A considerable amount of the farmer’s time had to be devoted exclusively to its care; much of the output of the farm had to be used as feed; and at least part of the farm’s acreage was reserved for pasture.

The development of agricultural machinery was inhibited as long as animals were the only available source of power. Designers were forced to gear their machines to the speed of the horse and make their draft no heavier than an ordinary team could pull. Some kind of power more efficient than that which animals were able to provide was clearly indicated if industry was to continue its service to the farmer by giving him machines that would allow him to get the most out of his land with the least effort.

It was only natural that after the invention of the steam engine there should be experimentation with the use of this mighty new source of power on the farm. The first, and what was to be the only really practical widespread application of the steam engine, was in threshing, during which power was transmitted by a belt to the threshing machine. Throughout the last century, many attempts were made to apply the steam tractor to plowing, the farmer’s most difficult job. There was no question but that the steam engine was an aid in plowing, but its use was extremely limited. Because of its cost, size, and general unwieldiness, it could be employed profitably only on the immense acreages of the West. Farmers or quarter and half sections never seriously considered the steam tractor. Its real importance lay in the fact that it was a step in the right direction. Its existence gave rise to the first efforts to design and manufacture a tractor that could employ the internal combustion engine beginning to be a seriously considered development about I900. As the internal combustion tractor emerged

- Earliest IH tractors, such as this 1906 model, were manufactured jointly by International Harvester and the Ohio Manufacturing Co. -

from its experimental stages, the steam tractor was doomed.

The first internal combustion tractors built near the beginning of this century were patterned after the steam models. Often their building simply involved the replacing of the steam unit with an internal combustion engine. Consequently, the pioneer tractors embodied many of the same faults: they were still too heavy; they were unreliable to the point that they broke down about as often as they ran - and nearly all of them had an alarming tendency to dig themselves into mud holes whenever the going was at all bad. During those first years, designers were convinced that there could be neither power nor traction without great weight. The efforts of all progressive farm tractor manufacturers have since been directed toward lessening its weight per horsepower.

As might be expected in an organization so sensitive to the needs of the farmer, International Harvester was one of the first companies to explore the possibilities of this new kind of power. As early as 1889, the Deering Harvester Company began to experiment with a gas engine and, by the time of the formation of the International Harvester Company, was producing almost 50 stationary engines a day that could be mounted on various Deering implements. In 1900, E. A. Johnston of the McCormick Harvesting Machine Company designed an auto mower, the outgrowth of several years of experimentation with the internal combustion engine.

- Dapper owner of 1900 Auto-Mower foreshadowed the boom in power lawn equipment by more than 50 years.-

Experimental work on the first International Harvester tractor began in 1905 at the former Rock Falls Works under the supervision of Mr. Johnston. This was a cumbersome three-wheeled machine with a single wide wheel in front. The following year, the Company put its first tractors on the market. These were built under an arrangement with the Ohio Manufacturing Company of Sandusky, Ohio, which supplied the truck and transmission on which an International engine made at Milwaukee Works was mounted.

- 1913 Mogul tractor supplied plenty of power but was too bulky and costly for all except the largest farms. -

Meanwhile the Internacional Harvester Company proceeded with its experimental work at Akron and McCormick Works, producing the first all-International tractors at Akron in l908. In 1909, one of these tractors crossed the ocean to Amiens, France, where in a memorable contest it received the medal of honor for plowing for two days without a breakdown. By 1910 International Harvester's Mogul and Titan tractors represented a third of the nation’s production, and Tractor Works in Chicago had been built for their exclusive manufacture.

Up to and during the first World War, tractor manufacture continued to be characterized by the building of huge, unwieldy machines, strongly influenced in design by the steam engine. This emphasis upon the production of large tractors was caused largely by the urgent need of the large farmer, who was the first to feel the inadequacy of animal power. A small farm could still be operated profitably with animal power, but the volume of work in the large acreages of the West was more than horses and mules were capable of handling efficiently.

The incentive provided by the huge wartime demand for tractors led many automobile manufacturers into the farm power field. The influence of automotive design led to many changes in the farm tractor and began a trend toward a smaller machine, more suitable for the ordinary small farm of the Middle West. Some manufacturers, failing to grasp the essential differences, tried unsuccessfully to convert the automobile into a tractor. There was a middle group, however, that was fully aware of these differences but saw a possibility of applying many of the principles of automobile manufacture to the tractor without sacrificing any of its simplicity or necessary ruggedness. In this category was the International Harvester Company, which gradually altered the design of its tractors, making them lighter and embodying in them more precision construction.

International Harvester engineers had been working for many years on a tractor, which, unlike the standard four-wheeled machine, could be used effectively for cultivating row crops. The first such attempt was a motor cultivator, produced experimentally in 1915. Because of its high manufacturing cost and limited utility, this machine was dropped from production in 1919 in favor of concentrated experimentation on an all-purpose tractor. Up to this time, it had been felt in many quarters that two tractors would be necessary for the efficient operation of a farm without animal power: a conventional four-wheeled model for all duties except cultivating and a motor cultivator of some type.

- It was the IH Farmall tractor, introduced in 1922, that revolutionized the industry: it was the first successful all-purpose tractor. –

The Farmall model was the first successful attempt at building a genuine all-purpose tractor. Its advent in 921 revolutionized the tractor industry. During that year, 10 of the experimental Farmall tractors were sent to the field for testing and careful observation by International Harvester experts. In 1923, 26 more were sent out for trial after further field-tested refinements had been made. The following year regular production on a limited schedule was begun at Tractor Works.

A landmark in tractor production was reached in October 1926, when production of Farmall tractors was begun at the newly equipped Farmall Works in Rock Island, Illinois. The Farmall tractor has undergone many changes in power and utility since the day it started rolling off the assembly line at the new plant, which had been built solely for its production. Though each year has seen important refinements, the essential features have remained the same: the high rear-wheel drive for maximum clearance under the rear axle: the small, narrow front wheels designed to run between row crops: and the means of mounting implements and other attachments on either the front or the rear. Through its ability to perform not only the belt and drawbar functions of the standard four-wheeled tractor but also co work efficiently in row crops, the FarmalI tractor made possible for the first time the horseless farm. After its introduction, all tractor manufacturers followed the international Harvester example with machines of similar design.

Even before the introduction of the Farmall tractor, the International Harvester Company pioneered in the development of the power take-off, which, when it appeared in 1918, finally eliminated the necessity for the ground drive wheel. This feature permitted direct transmission of power from the tractor to the drawn machine, minimizing loss of power and opening the way to design of lighter, more compact implements. By 1934, power take-off had been built into nearly every tractor on the market.

After the development of the power take-off and the successful entry of the FarmalI into the farm tractor field, revolutionary changes took place in the design of all farm machinery. Equipment was designed to be mounted directly upon the tractor, much of it easily detachable and removable by one man. Thus, an implement became an integral part of the tractor itself, permitting a lighter, less expensive construction, yet much higher speeds than could be attained with animal power. The use of a tractor equipped with a power take-off allowed all harvesting machinery to employ a wider cut and high-speed gearing.

A further improvement was the introduction of pneumatic-tired tractors in 1933. Although they increased the original cost of the tractor, rubber tires had many advantages, the most important of which Was the lessened rolling resistance and consequent reduction in fuel costs. Rubber tires for the first time admitted the tractor to the paved highway, and in valuable aid in moving equipment from one field to another on farms crossed by important roads. Their cushioning action added greatly to the life of the tractor and the comfort of the driver. The success of the Farmall design induced manufacturers to give more attention to the needs of the small farmer. International Harvester Company led the way in the direction with the Farmall 12, the first of the one-plow tractors. This was followed in 1939 by the Farmall A and B, even smaller and less expensive machines. The Farmall Cub was finalized for production in 1945 – ready to serve all the purposes of the nation’s smallest farms. These small tractors brought with them, as collateral developments, equipment also adapted to the farm of limited acreage. This equipment could be mounted on the tractor or used with the power take-off in the same manner as the larger machines.

Growth of the International Truck Business

International Harvester Company's entry into the field of motor transportation was inspired by a recognized need or the farmer. By the end of the last century, rural America had become so spread out and farm production had increased so enormously that transportation threatened to become a bottleneck. Farmers who were not located near a railroad were finding the horse and wagon an utterly inadequate, time-consuming means of hauling their produce to the market. Trips to town were necessarily infrequent when they involved an expenditure of long hours or days of indispensable horse and manpower. America’s farmers needed a method of transporting themselves and their produce with speed and dependability. The first groping in the direction of a gasoline-powered horseless carriage seemed to indicate the solution to this problem.

At the same time that it began to experiment with its first tractors, Internacional Harvester became interested in the development of a farm truck. For many years before management was officially committed to the idea, the Company's engineers had been testing versions of a vehicle suited to the needs of the farmer. As early as 1898. E.A. Johnston of the Engineering Department had installed a gas engine in a wagon-type chassis and driven it successfully between his home and McCormick Works for many months.

In 1905, after several more years of experimentation, Mr. Johnston designed and developed an Auto Buggy at the Rock Falls Works. This was a two-cylinder, air cooled engine mounted on a high wheeled chassis, designed to look as much as possible like the traditional horse-drawn buggy. It was to serve the same purpose - to haul moderate amounts of produce to and from the market and take the farmer and his family to church on Sundays.

In the early spring of 1907, I00 of these Auto Buggies were put into production in a part of McCormick Works that had been set aside for the purpose. The quick acceptance of the Auto Buggy and the subsequently developed Auto Wagon appeared to justify their production on a regular basis, so the assembly line was moved later that same year to Akron Works, where more adequate facilities existed. This was the first of the Company's truck plants.

- ln 1910, a brief venture into the passenger automobile field – with roadsters and tour cars. -

Here also the Company made a brief venture into the manufacture of passenger automobiles, when, in 1908, Mr. Johnston designed a roadster and a touring car, both equipped with four-cylinder vertical engines, the first in automotive history to use overhead chain-driven camshafts. After approximately 1,500 of these models had been produced in 1910 and 1911, the Company decided to abandon the manufacture and sale of automobiles and concentrate on the engineering and manufacture of trucks.

During the years that followed, the design of the International truck was gradually weaned away from the original high-wheeled Auto Buggy and began to assume the lines of today's conventional truck. Just as was the case with the tractor, the heavy demand for motor transport created by the first World War stimulated the manufacture of all models of trucks. From 1915 on, the Company developed the prototype of the present International truck and the demand from urban consumers began to outstrip that from the farm.

By 1911, it became apparent that facilities at Akron Works would soon become inadequate to handle the increased volume of truck production in all models. Accordingly, truck manufacture was instituted at Springfield Works, home of the old Champion line of farm equipment that had only recently been discontinued.

At the same time the Company determined to build a modern plant suitable to modern mass production methods to house the manufacture of its line of heavy-duty trucks. After careful deliberation, Fort Wayne, Indiana, was selected as the plant construction site: construction began in 1922. By 1923, Fort Wayne Works, a thoroughly modern factory in every respect, produced its first vehicle. Akron Works was closed in 1925. By that time, International Harvester had become the country's largest manufacturer of a complete line of trucks and was producing a vehicle for every important agricultural and commercial need, with the latter predominating. The volume of truck production had reached a point by 1937 that justified the erection of a plant to be devoted exclusively to the production of truck engines. Indianapolis was chosen as the location for this plant because of its position approximately 150 miles from both Springfield and Fort Wayne. The first heat was poured in the plant's foundry in July, I939. Expanded and modernized since that time, production of truck engines of alI types has steadily increased at Indianapolis plant.

- In 1917, International Model F trucks were pressed into duty for the Red Cross. -

International trucks have long been famed for their ability to stand up under tough conditions. The high-wheeled construction of the original Auto Buggies and Auto Wagons was designed to allow these vehicles to traverse the muddy, rutted country roads the average farmer was forced to cope with. Only after improvement had been made in the national highways was the diameter of the wheel reduced.

- The IH “K” Line made its debut in 1944, but some are still seen on the highways! -

At Fort Wayne, a proving ground containing a severe twist course and roads studded with Belgian paving blocks was completed in 1929 to assure that all models received a thorough scientific testing under the most arduous conditions possible before being offered to the customer.

Development Of the International Construction and Industrial Equipment Lines

A natural outgrowth of International Harvester Company’s efforts in the direction of providing power for the farm was the development of power for many kinds of non-farm purposes. It was only logical that the tractor that had been perfected by the Company should find its way into other uses, where the need for power was just as acute. Records indicate that, as early as 1912, an Internacional Harvester Titan tractor was designed to be convertible into a road roller by the removal of the front wheels and insertion of four 15-inch rollers.

Tractors became really practical for construction and industrial use, however, when the regular McCormick-Deering 10-20 farm tractor was equipped with solid rubber tires in 1924 to make the tractor suitable for use on paved highways and within factory buildings. Five years later, the large McCormick-Deering 15-30 was similarly equipped to give industrial users the benefit of added power.

In 1928, the 10-20 was modified by the addition of a tracklaying device to make the first International crawler-type tractor. Later International crawler tractors were built with more and more horsepower to meet the needs of heavy construction and logging work, and also to satisfy the demand from farmers who need the extra power and traction of the crawler-type tractor to pull heavy combines and gang plows over the immense hilly acreages of the West. By 1933, the first diesel engine was installed in an International crawler tractor, the TD-40. This was the first American-made diesel engine that started on gasoline and after a minute or less shifted to full diesel operation.

By the time pneumatic tractor tires had been introduced, International Harvester was manufacturing a greatly broadened line of tractors for industrial and construction use. This innovation gave the tractor greater mobility and a wider variety of uses – particularly in airports, large factories, and enterprises in which there is a problem of handling heavy materials. At this time, too, international truck and tractor engines were being adapted to industrial use as power units for machines made by other manufacturers. In 1938, International Harvester produced the TD-18, its first tractor designed for exclusive industrial application. No longer were industrial tractors simply modifications of farm tractors; an entirely new field had been opened with its own distinctive characteristics.

International Harvester Mogul 12-25 Tractor 1913-1919

The Mogul, although not the first tractor of record, is representative of the type being made when farmers first began to replace the horse as the major source of farm power.

The first tractor used for field work was a steam powered, overweight giant which first replaced a horse in 1855. However, the "modern" tractor waited on the development of the internal combustion engine.

In 1876 N. A. Otto and Eugene Langen made a practical power unit using a "free-piston." Otto's patents expired in 1890, and in 1897 the McCormick Company built its first gasoline engine.

In 1899 S. S. Morton built a successful tractor which was, in effect, a self-propelled power plant to take the place of a portable engine. He took out patents on a traction truck mounted with a gasoline engine in 1902 and 1903. These were soon bought by the Ohio Mfg. Co., Upper Sandusky, which demonstrated them for International Harvester. IH bought several in 1905, and for a few years tractors sold by IH were built by Ohio Mfg. Co.

In 1906 International Harvester started building a 10-hp tractor, and in 1908 the first all-international tractor was in production.

In 1910 International built the 45-hp Mogul at the Chicago Tractor Works. The 2-cylinder engine had open tower cooling, a "hit-and-miss type flyball governor," low-tension "make-and-break ignition," and spur gear transmission.

In 1911 the larger, 2-cylinder 30-60 (30 dbhp-60 bhp) Mogul, was introduced with throttle governor and other improvements.

In 1912 came the 15-30 Mogul. Its one-cylinder engine had a force-feed oiler, a pump and tower cooling, hightension magneto, friction clutch, and spur gear final drive.

The year 1913 saw the 12-25 Mogul in production. It had a 2-cylinder engine, single plate disk-type clutch, chain drive, automotive-type steering, and jump spark ignition.

In 1914 the 2-plow, 8-16 Mogul came on the scene. This single-cylinder engine was hopper-cooled, had planetary gear transmission, single chain final drive, and belt pulley mounted on flywheel.

In 1916 the last of the Mogul tractors, the 10-20, was introduced. It was a slightly larger version of the 8-16 and featured a 2-speed sliding gear transmission.

From the early days through final production in 1919, a total of 20,385 Mogul tractors was produced. Prices ranged from $675, f.o.b. Chicago, for the 8-16 to $2,475 for the 30-60.

International Harvester Titan 10-20 Tractor 1914-1924

As American Farmers began in earnest to replace the horse with tractor power during and after World War I, Titan tractors, introduced in 1910, reached a high level of popularity. In 1919 there were 13, 753 Titan tractors sold; the next year 14,362. Most popular was the 10-20.

In 1910 the 45 hp Titan, made at Milwaukee Works, was introduced. It had a 2-cylincier horizontal engine, force feed oiler, "make-and-break" ignition, "hit-and-miss" governor, pump and tank cooling, spur gear transmission, final drive live axle.

In 1911 the IHC Titan road roller/ tractor combination was made available in 20 and 25-hp sizes and featured a single-cylinder, four-cycle engine. Easy to convert from road roller to hauling tractor-front trucks bolted to same vertical pin.

In 1913 the 45 became the 30-60 Titan with a 30 dbhp-60 bhp rating. It was started with a one-hp air cooled engine and friction starter.

In 1913 the 18-35 Titan, a twin cylinder, was introduced. It had a ¾-hp air-cooled engine, air compressor, and air storage tank for starting. Had sliding gear-type transmission with friction clutch. Featured a two piece removable cab with side curtains and spring hung seat platform.

In 1914 the popular 10-20 Titan was introduced with twin cylinder, horizontal, kerosene burning engine. A valve automatically supplied water to the fuel mixture in proportion to fuel being used. It was equipped with a high-tension magneto with impulse starter (no batteries needed).

The 10-20 Titan had automotive type steering with enclosed worm gear, and spur-gear, selective-type transmission with double chain drive transmission turning on a dead axle.

A feature of the 10-20 was the improved thermosiphon closed colling system in which water was circulated by steam impulse. (In open, and some earlier closed systems, the cooling air was circulated by induced draft from the exhaust or by fan, and the water circulated by plunger or rotary pump.)

In 1915 the 15-30 Titan was brought out. It had a four-cylinder double twin, horizontal engine with a mechanical oiler. Its mixer had four needle valves for fuel and one for water. (In 1918, the 15-30 Titan was replaced by the International 15-30.)

From the early days through final production in 1924, a total of 60,969 Titan tractors were produced. Prices ranged from $900, f.o.b. Chicago for the 10-20 to $2,350 for the 30-60.

International Harvester McCormick-Deering 10-20 1923-1942

The “Cinderella of farm tractors” could describe accurately the McCormick-Deering 10-20. Delegated to the hedgerows in the 1930’s by the McCormick-Deering Farmall family which revolutionized “row-crop” farming, the depended 10-20 was rediscovered and appeared nobly on countless American farms during World War II when farm equipment output was cut back to make way for war tools. Farmers and their 10-20’s and faithful 15-30’s, partners in hard work, teamed up to successfully accomplish the awesome job of feeding the Allies.

First introduced in 1923, the McCormick-Deering 10-20 had the speed to cover ground quickly and to hurry important work when weather demanded. It had ample power to pull plows under average soil conditions at three miles an hour, pulling deep. The 10-20 and 15-30 both featured a revolutionary four-cylinder vertical engine of valve-in-head construction which operated economically on kerosene and started on gasoline. It was equipped with removable cylinders that were easily replaced, making a practically new engine at small cost.

First-year production of 10-20’s totaled 7,150. This increased each year, reaching 34,742 in 1929, the peak year of production. The depth of the depression and competition from the Farmall line dropped output to 40 in 1933. It staged a mild comeback in the mid-30’s with 2,953 units produced in 1936. The final year of production was 1942. A total of 215,793 sturdy 10-20’s were manufactured.

Testimonials for the 10-20 increased each year. From Williamstown, Mo., in the tough gumbo soil of the Fabius River bottom, came the report in 1924 that a field overgrown with rank weeds had defied all previous attempts to plow it. Despite tough soil, heavy weeds, and water which rain into the furrows as fast as they were plowed, the 10-20 performed the feat with two 14-inch bottoms. This tractor conquered the hills of the eastern states, where it was thought only horses could prevail.

Commendations for the 10-20’s even power in pulling a grain binder came from France. From a Chinese missionary college came praise for the 10-20, as it turned useless, hilly land into good farm ground by its ability to plow deeper than oxen.

The steady power of the 10-20 made power-driven binders more popular each year. Cutting 30 to 40 acres in an ordinary day set new highs in productivity. It clipped three acres easier than 1 ½ acres were clipped before. A famous-name auto manufacture tried to drive International Harvester out of the tractor business in the 1920’s with an English-made model, but the rugged 10-20 battled this particular unit into oblivion.

A contemporary of the 10-20 was the famous McCormic-Deering 15-30, usually described as the “Faithful Old 15-30.” It had 15 horsepower on the drawbar and 30 on the pulley. In 1930, horsepower was increased to 22 on the drawbar and 36 on the belt.

Rated a 3-plow tractor, the 15-30 was built from 1921 to 1934, close to 156,000 units produced. Chief difference between the 10-20 and the 15-30 was size. These were the first tractors regularly equipped with a power takeoff, described in promotional material of 1924 as that which “consists of a shaft attached to the rear of the transmission. It transmits power in much the same way as a propeller shaft on an automobile or truck and is used to drive the mechanism of the pulled machine.”

In 1923, the 10-20 was listed at $785; the 15-30 at $1250. By 1939, the 10-20 was listed at $950 with steel lugs, and $1158 with rubber tires.

If it isn’t a McCormick-Deering, it isn’t a Farmall.

This slogan characterized the beginning or International Harvester's dominance over the all-purpose farm tractor field in the 1920's and 1930's. Eliminating the need for horses, even in row crops, was the concept behind the Farmall tractor first sold in 1924 and mass produced in 1925.

This concept and the tractor itself was many years in developing, starting about 1915. In planning the Farmall, IH officials demanded that it be lightweight. It weighed about 3,300 pounds, in sharp contrast to the 21,700-pound Mogul in 1911. Above all, the Farmall had to be able to cultivate corn and other row crops and do belt work.

The original Farmall was capable of pulling a plow with two 14-inch bottoms, was designed to meet the requirements or farms in the quarter-section class. There were many conditions under which it could pull three bottoms. Horsepower ratings were avoided, but in Oklahoma, where a rating was required, it was classed as 9 horsepower. In Canada, it was rated 9 on the drawbar, 18 on the pulley.

One man with a Farmall could intensively farm up to 200 acres; replace up to 18 horses and two to three men; plow seven to nine acres a day; double disk 18 to 25 acres a day: drill 45 acres a day; plant 50 acres a day; cultivate 30 to 50 acres a day; or mow 50 to 60 acres a day. In 1931, the original Farmall was superseded by two Farmall tractors, the F-20 arid F-30. The F-20 compared with the 2-plow original Farmall. The F-30 was the three-plow size, meeting the requirements of farms in the 200 to 300-acre class or smaller farms where power demand was greater because of soil conditions.

First sold in 1932, for the smaller farm the F-12 was rated for one 16-inch plow bottom or two I0-inch bottoms. The F-14 replaced it in 1938.

Early Farmalls were painted gray with red wheels. But beginning Nov. 1, 1936, Farmalls were painted all red, which was considered a safety factor since Farmall tractors were by then moving freely on public roads.

Comparisons of Farmalls and mules in raisin cotton in Arkansas showed that costs were cut S5.51 an acre by the Farmall. A comparison published in 1932 indicated that the cost of raising an acre of wheat with horses would be $2.78 an acre more than with a tractor, even if horse feed could be obtained free.

Other big advantages were convenience and savings in time. Nebraska farmer George G. Gowen, claimed he could "do all the maintenance on my Farmall and have it going in the time it formerly took for my horses to take a drink of water."

From 1922, when 100 were built for testing but not for sale, through 1925, a total of only 1,114 Farmall tractors were produced at the IH Chicago Tractor Works. Only 26 were built in 1923. Most of the early ones were tested by and sold to farmers in Texas.

In October 19 26, all-out production was started at the Rock Island, Ill., plant named Farmall Works which was purchased from the Moline Plow CO. in 1924. Through 1938, total Farmall tractor sales reached 420,460.

Because the tractors were being built by hand, the 1924 sale price of $825 resulted in a considerable loss to the company.

Advertisements:

WELSCH BLOCK CO. 1920-1979. RED-E-MIX CONCRETE. BUILDING MATERIA. SERVING THRESHERS FOR 59 YEARS. Welsch Red-E-Mix. 806 GARDNER ST. JOLIET 726-6261

23rd ANNUAL STEAM SHOW and THRESHING BEE. THE SYCAMORE SHOW. TAYLOR MARSHALL FARM, SYCAMORE, ILLINOIS 50 miles west of Chicago 1½ miles north of Sycamore, IL on Rte. 23 to Plank Road, then two miles east. AUGUST 9-10-11-12, 1979. THRESHING DAILY USING STEAM POWER. Open 7:00 a.m. to 6 p.m. Steam Engines - Gas Engines - Gas Tractors - Steam powered Sawmill - Concession Stands - Ladies' Hobby Tent, Antique Display, Tread Mill, Flink Fan, Stagecoach Rides, Flea Market. Wilder Fay's PORK CHOP Barbecue and Chicken Barbecue Meals. Charter Grove Grange Breakfast-Sandwiches. ADMISSION Adults - $1.50. Children under 12 free. FREE PARKING. NORTHERN ILLINOIS STEAM POWER CLUB. A Not-For-Profit Organization. Write Kathleen Levine, Secy. 858 Leonard Ave., DeKalb, IL 60115 Greater Sycamore Chamber of Commerce Phone: 895-3456

THERE'S A SAVINGS ACCOUNT IN LOCKPORT THATCAN GIVE YOU AFREE CHECKING ACCOUNT. AND MORE. THE PIONEER CLUB. This unique type of savings account is called the Pioneer Club and is available only at the Bank of Lockport. Your Pioneer Club account will give you a valuable combination of services In one convenient package. Pioneer Club members get a free checking account. Your account will be free of service charges, free of per check charges and free of minimum balance requirements. You will also be able to buy travelers’ checks with no service charges. You'll save SS on every $500 you buy. Plus, it's the 'safe way' to carry money. You'll have an autom1tic loan privilege up to $1,500. You can borrow whenever you need it, without unnecessary red tape or waiting. Certified cashier’s checks will be available to you without any service charges. And they add extra security when making large payments or ordering by mail. Many other banks will be ready to cash your check (up to $50) with normal identification. Each is a member of Security Check. They are located as far west as Aurora, as far east as Chicago, and in such convenient locations in between as the Oak Brook shopping center. All you have to do to join the Pioneer Club is keep a minimum balance of $1,000 in your regular Bank of Lockport savings account. You'll get these free services, plus earn 5% interest on your savings. Stop in the Bank of Lockport today or return the enclosed card to reserve your Pioneer Club membership. You'll see how much more a savings account can be! 826 EAST NINTHSTREET • LOCKPORT, ILLINOlS 60441 • 115/131-1800 • MEMBER FOIC

PEOTONE BANK and TRUST CO. 200 WEST CORNING AVENUE PEOTONE, ILLINOIS 60468 (312) 258-3231. ASK ABOUT OUR "BANCLUB" LOANS; QUICK & EASY. MEMBER FEDERAL DEPOSIT INSURANCE CORPORATION. "The Bank of Friendly Service”

Serving Agriculture from Steam to Diesel 1927-1979. The New Lenox ·State Bank now has two locations to serve our customers. Our New Motor Bank at 360 W. Maple Street 5 lanes for Drive-up Service, plus 4 Lobby Windows. New Lenox state bank. 110 W. MAPLE STREET / NEW LENOX, ILLINOIS 60451 / 815 / 485-7500. 360 W. MAPLE STREET / MOTOR BANK / PHONE 815 / 485-7550. LARGEST BANK IN THE LINCOLN WAY AREA! MEMBER FDIC

FIRST NATIONAL BANK OF MANHATTAN. MEMBER F.D.I.C. PHONE: 478-3252. SERVING ALL FARM FINANCIAL NEEDS. 1902 – 1979. BANK HOURS: Lobby and Drive-Up Monday 8 a.m. - 3 p.m. Tuesday 8 a.m. - 3 p.m. Wednesday - CLOSED Thursday 8 a.m. - 3 p.m. Friday 8 a.m. - 6 p.m. Saturday 8 a.m. - 12 noon

PIONEER SEED CORN DEALER. Edward McDonald. Route 3 Joliet, Illinois. “THIRTY YEARS OF SERVICE"

RUSSELL PRINTING CO. PUBLISHERS Main Office: 111 N. First Street Peotone, Illinois 60468. PUBLISHERS OF THE Peotone Vedette- Beecher Herald- Monee Monitor -Manhattan American – Crete Record - STEGER NEWS. Gilbert L. Russell & Lanson W. Russell Publishers. Serving All of Eastern Will County. Phone 312/258-3474

BENCK'S. Turf Nursery and Vegetables. C. Benck Rt. 52 Manhattan, Ill. 60442. 815-478-3116

TY-WALK LIQUID SALES, INC. Liquid Fertilizer. Dry Blend Fertilizer. Nitrogen Solutions. ANHYDROUS AMMONIA. Grain Drying & Storage. Custom Spraying. ON U.S. 52. PHONE: 462-5933. MINOOKA, ILLINOIS

FIRST NATIONAL BANK WILMINGTON, ILLINOIS. YOUR PARTNER IN PROGRESS. 476-2141

JACOBS ACE HARDWARE INC. Harold, Ron & Dan. TRACTOR AND FARM IMPLEMENT PARTS. DEKALB SEED CORN. RT. 50 SOUTH MANTENO, ILLINOIS

DRAKE LUMBER & HARDWARE, INC. 838-5000. LOCKPORT, ILL.

COLDWATER SEED FARM. SEED CLEANING AND TREATING. Phone -- Elwood 815/ 423-5357

NEW LENOX LUMBER & HARDWARE CO. 380 N. Cedar. NEW LENOX, ILLINOIS. Phone 815-485-2101

GAST INTERNATIONAL, INC. Laraway and Cherry Hill Rds. Joliet, Illinois 60433. (815) 726-4248. Complete Line of: Farm Equipment Payline Equipment, Payline Equipment, Lawn and Garden Equipment

MERLE JONES & SONS INTERNATIONAL TRUCKS. DETROIT DIESEL – CUMMINS – CATERPILLAR. PHONES: (815) 725-9550 or (312) 242-1976. SERVICE: 725-0560. PARTS: 725-4042. NIGHT SERVICE. 103 South Larkin Avenue (Near 1-80) Joliet, Illinois 60436

TROJAN SEED CORN DEALER Route 2 MANHATTAN, ILL. 60442. PHONE 478-3856. VIRGIL M. LAWLER & SON

WILL COUNTY FARM BUREAY AND AFFILIATED COMPANIES. SERVING AGRICULTURE IN THE COUNTY FOR OVER 50 YEARS. WILL-DUPAGE SERVICE CO. SERVICING PROGRESSIVE FARMERS WITH: PETROLEUM, FEED, PLANT FOOD, GRAIN, LP GAS. FS. 6700 MEMBER FAMILIES. COUNTRY COMPANIES INSURANCE AGENCY: CHARLES R. HULL, CLU, AGENCY MANAGER. LEWIS WERNER, FRANK TOWNSEND, ROCHO SINDERSON, WAYNE KARSTENSEN, JAMES McGUIRE, NORMAN GILL, BRUCE BISSELL, DONALD SHIPLEY, DONALD LOWTWAIT, DONNIE BURGIN, T. LAMAR WAGNON, JAMES ZUKOWSKI, JAMES JANDA, DANIEL MURPHY, J. MICHAEL DONAHUE, LARRY STEPHENS, ROBERT RADEMACHER, KURT WINTERROTH, LESTER HEBERER, JAMES LETTERLE

HEITMAN TRUCKING COMPANY Est. 1940. "Friendly and Dependable" Service. DRIVEWAY STONE OR GRAVEL SLAG, SAND OR STONE FILL, BLACK DIRT OR CLAY (when available), YARD CLEAN UP (garbage), MACHINERY MOVING. (815) 478-3156 - 7:00 a.m. to 6:00 p.m. (815) 478-3084 - 6:00 p.m. to 10:00 p.m. 435 STATE ST. MANHATTAN, ILL. 60442

FIRST NATIONAL BANK OF JOLIET. OFFERS A COMPLETE FARM SERVICE DEPARTMENT. WILLIAM RANDLES Sr. Vice-President. ROLF E. VOGEN Assistant Vice-President Farm Manager. DAN FRIANT Farm Manager & Farm Loan Officer. WAYNE HUFFMAN Vice-President & Trust Officer. WHEN YOU BANK . . .. .THINK FIRST! PHONE: 815-726-4371. MEMBER F.D.I.C. first national bank of Joliet. 78 No. Chicago St., Joliet, Illinois 60431. TEL 726-4371. Member FDIC.

HAUCK SERVICE STATIONS. THE VERY BEST IN GASOLINE. DISCOUNT PRICES EVERY DAY. JOLIET: 509 E. WASHINGTON ST., MANHATTAN RD. and RICHARDS ST., 1621 W. JEFFERSON ST., STATE ST., LOCKPORT, ROUTE 66A WILMINGTON, ROUTE 30 NEW LENOX, ROUTE 52 MANHATTAN, ROUTE 53 ROMEOVILLE, 1st & GARFIELD HINSDALE, ROUTE 53 BOLINGBROOK, WOLF ROAD, MOKENA, ROUTE 6 CHANNAHON.

AMOCO OIL COMPANY. LIQUID FERTILIZER, ANHYDROUS AMMONIA, AG CHEMICALS SPRAY EQUIPMENT, SOIL TESTING, CUSTOM SPRAYING. SYMERTON PLANT. Rick Gallagher, Mgr. Phone: 476-7109

Lambrecht agency. Farm Insurance Since 1917. FARM BLANKETS AND FARM LIABILITY. Life and Health Insurance for Farmers. 515 LaGrange Road. P.O. Box 370 Frankfort, Illinois 60423. 815/469-2326. 312/479-2146

JOLIET AUTO SUPPLY INC. 314 HENDERSON, JOLIET, ILL. 41 Years at the Same Location. Over 300 Years of Combined Automotive Experience. PHONE 726-4729 AND 726-7668. Machine Shop Service. Complete Line of Car - Truck – Tractor and Lawnmower Parts. Plus Foreign Car Parts Datsun-Toyota-Yolks-Opel. HOURS - MON-FRI 8-5 SAT 8-2

CARGILL, INC. Nineth Street at Channel Lockport, Illinois. SERVING AGRICULTURE FOR MORE THAN A CENTURY. Phone 815/838-1153. HARRY LARSON, Manager

DELLWOOD TIRE ·& AUTO SUPPLY CORP. Passenger - Truck – Tractor. Batteries, Front End Alignment, Brakes & Shock Absorbers, Exhaust Systems. Complete Line of Auto Parts. WHOLESALE & RETAIL. Michelin. Firestone. PASSENGER TIRES 838-5067, TRUCK TIRES 838-3380, AUTO PARTS 838-8300. 616 STATE STREET LOCKPORT, ILLINOIS 60441

AGRO INC. Liquid and Ory Fertilizer, Farm Chemicals, SoiI Testing. Anhydrous Ammonia, Arcadian, Nitrogen Solutions. R. #2, Monee, Illinois. Vince Toepper, Mgr. Phones: 815-469-2769

Tabor Grain Co. Div. of A.D.M. CASH GRAIN COMMODITY BROKERS Gordon Neubauer, Manager. 450 S. Center Street Joliet, Illinois. Phone 726-5227

JOLIET GRAIN CO. & BIRDS BRIDGE ELEVATOR. COMPLETE WAYNE FEED SERVICE GRASS SEED AND FERTILIZER ROCK SALT - - BULK DELIVERY GRAIN DRYING - - GRAIN STORING. Joliet Grain Co. Interstate 55 & Rte 6 Channahon, Ill. Phone 725-5790 Tom Malone, Mgr. Birds Bridge Elevator Route 3 Joliet, Illinois. Phone 725-1540

RICHARD McHUGH REAL ESTATE – INSURANCE. 478-3772. Route #2 Manhattan, Illinois

CHRISTENSEN POWER EQUIPMENT INC. MONEE-MANHA TT AN ROAD NEAR CENTER ROAD. 5 MILES SOUTH OF FRANKFORT. Phone 815/469-5898. LAWN & GARDEN EQUIPMENT, WHEEL HORSE, ARIENS JACOBSON, LAWN BOY, ARCTIC CAT SNOWMOBILES. Earl Christensen, Ron Christiansen, Rich Kuse, Rick Steinberg.

FRANKFORT HARDWARE. Specialists in: WATER SERVICES, AEROMOTOR PUMPS, WATER SOFTENERS, WATER HEATERS, PLUMBING SUPPLIES. Frankfort, Illinois. Phone 815/ 469-2159. Mike Griffin.

Heritage Bank And Trust Company. 1660 North Plainfield Road Crest Hill, Illinois 60435. (815) 729-1850. JOHN W. D'ARCY President.

PEOTONE FARMERS ELEVATOR ASS’N. GRAIN, FEED, SEED, LUMBER, BUILDING MATERIALS. Peotone, Illinois. Phone 258-3277

LINCOLN-WAY SAVINGS & LOAN. “Where Savings Earn More.” Now 2 Locations. 500 W. Maple New Lenox, IL 60451. 815-485-2186. Mokena, IL 11124 Front St. 815-479-2491.

EBERT FARM SERVICE. FEED - FERTILIZER – GRAIN. 19709 Mokena Street

Mokena, Illinois. Phone 479-9471

RITTENHOUSE AND EMBREE COMPANY. LUMBER – MILLWORK. ROBERT R. DEHN. FRANKFORT, ILL. Phone 815/469-3141

PETERSON MANUFACTURING CO. PETERSON DUAL WHEELS, AXLE MOUNT or UNI-TACH, CONTRACT MANUFACTURING MAINTENANCE and REPAIR. 700 W. 143rd St., Plainfield, Illinois. Phone 436-9201.

BAKER IMPLEMENT COMPANY 83 West First Street Manteno, Illinois 60950. Phone Area 815-468-3408. FARM EQUIPMENT. PARTS & SERVICE.

COMPLIMENTS OF Plainfield Tool & Engineering, Inc. PLAINFIELD, ILLINOIS. TOOLS - DIES - STAMPINGS

CONSUMER'S TRUE VALUE. 1917 – 1979. ZENITH TV - QUAZAR TV - SPEED QUEEN. PHONE 815-478-3317. CHEVORLET. MANHATTAN, ILLINOIS

PEOTONE SUPERMARKET. Peotone, Illinois. MANY THANKS FOR STORING THE MIX FOR OUR ICE CREAM MACHINE. W.C.T.A.

BEULAH'S CATERING SERVICE. Fine Food for Weddings, Parties, etc. Peotone, Illinois. Telephone: 258-6686. Catering Service.

Union National Bank and Trust. 50 West Jefferson Joliet, Illinois 60431. Your Money Service Center.

E&E. ENGINEERS and ENGINES Magazine. 25 Years of continuous bi-monthly publication. STEAM•GAS •TRACTORS FARM MACHINERY•RAILROAD. Expanding to cover Live Steam Locomotives and Clubs. DATES ON STEAM ENGINE SHOWS. Subscription Rate: $8.00 per year (Canada and Foreign Countries: $9.00) Sample Copy - send $1.50 postpaid. ENGINEERS & ENGINES MAGAZINE 1118 N. Raynor Ave., Joliet, Ill. 60435.

WELSCH BIG BUCK. BUILDING MATERIAL CENTER. ONE STOP BUILDING CENTER. ROUTE 45 and 1-80 Mokena, Illinois. Phones 312/479-2181. 815/485-2281. OPEN SUNDAYS.

ANDRES WILTON FARMERS GRAIN & SUPPLY CO. ANDRES. WILTON. P. 0. - Peotone, Ill. GRAIN, FEED, BUILDING MATERIAL. It will be our pleasure to SERVE YOU. Manhattan 478-3718. Peotone258-3628.

COCHRAN PLUMBING & HEATING, Inc. PUMPS AND REPAIRS, AIR CONDITIONING. PHONE 478-3192. OWNERS. BOBBORDEN, 56-068893. DON FAY, 58-082843. 35 S. STATE STREET MANHATTAN, ILLINOIS

JAMES TYLER & SONS. SINCE1927. ELWOOD, ILLINOIS.

ANDERSON AUTO SUPPLY. ANDERSON OIL COMPANY. The Leading Names in Auto Supplies and Oil Products. PHONE 634-2309. 130 BLACKSTONE AVE. COAL CITY, ILLINOIS.

DEKALB SEED. CORN DEALER. THE MAN WITH THE EXTRAS. HARLOW NICHOLSON ELWOOD, ILLINOIS. Phone 478-3516

PAT GORMAN. GORMAN AUCTIONEERING. Since 1926. AUCTIONEER and REAL ESTATE BROKER. "ALWAYS AVAILABLE" Peotone, Ill. Phone 312/258-6727. "IN AUCTION THERE IS ACTION"

NORMAN CHRISTIANSEN & SONS. BEEF CATTLE. Peotone, Illinois

SAM RAGUSA GARAGE. 1307 Collins St. JOLIET, ILLINOIS

LEYERLE OIL COMPANY. New Lenox, Illinois. Phone 485-2252

An Extra Measure of Service from GREEN GARDEN FARMERS MUTUAL FIRE INSURANCE COMPANY Monee, Illinois. Phone 815/469-5266. OVER 100 YEARS WITHOUT AN ASSESSMENT.

ALDEN MACHINE CO., INC. 312 HENDERSON AVENUE JOLIET, ILLINOIS 60432. Complete Machine Shop Service. Phone 815-723-9121

WELL DRILLING, ELECTRIC PUMPS, WATER CONDITIONERS. L. DELANEY Manhattan, Illinois. Phone 478-3664 Day or Night.

Frankfort state Bank "THE DAILY INTEREST BANK" WITH A DAILY INTEREST IN YOU' Frankfort, Illinois. Full-Service Bank. PHONE: 815-469-5100. Member FDIC.

HEATHERWICK CO., INC. ALLIS-CHALMERS - GEHL - VERSATILE – YAMAHA. SALES & SERVICE. Box 305 Frankfort, Illinois 60423. HEATHERWICK LEASING CO. "TRY IT!” 815/469-2108 - Business 815/469-2070 – Home.

COUNTY LINE SALES INC. JOHN DEERE SALES - PARTS – SERVICE. PHONE 258-3466. RT. #45 PEOTONE, ILLINOIS

CONTINENTAL GRAIN COMPANY P.O. BOX 115 LOCKPORT, ILLINOIS. 838-1801

THE MANHATTAN AGENCY. Phone 478-3350. 215 S. State Street Manhattan, Illinois. INSURANCE: JEANNE GREGG, GREG HOBBS. REAL ESTATE: GREG HOBBS, BILL ROBBINS, NANCY JAROSI, BOB EYRICH, JAN PETRINES, MILTON MORRIS.

SPENCER GRAIN CO. Coal - Wayne Feed – Grain. Bulk Delivery. New Lenox, Illinois. Phone 485-2211

THE KINGS ROW BARBER STYLING SHOP. Lincoln-way Shopping Center New Lenox, Illinois. Phone 485-6351. (On Route 30) Bud Huttenhoff, Bob Luzbetak, Sam Foster, Donna Kerschbaum

HANSEN'S. Red Fox Food Store & Villa Clothing Store. Women's & Men's Apparel. FAMILY OWNED & OPERATED. 395 State Street Manhattan, Illinois.

LEISER FURNITURE ''The Mattress King'' of ''Kankakee County'' Herscher, Illinois Est. 1892. CLOSED THURSDAY AND SUNDAY.

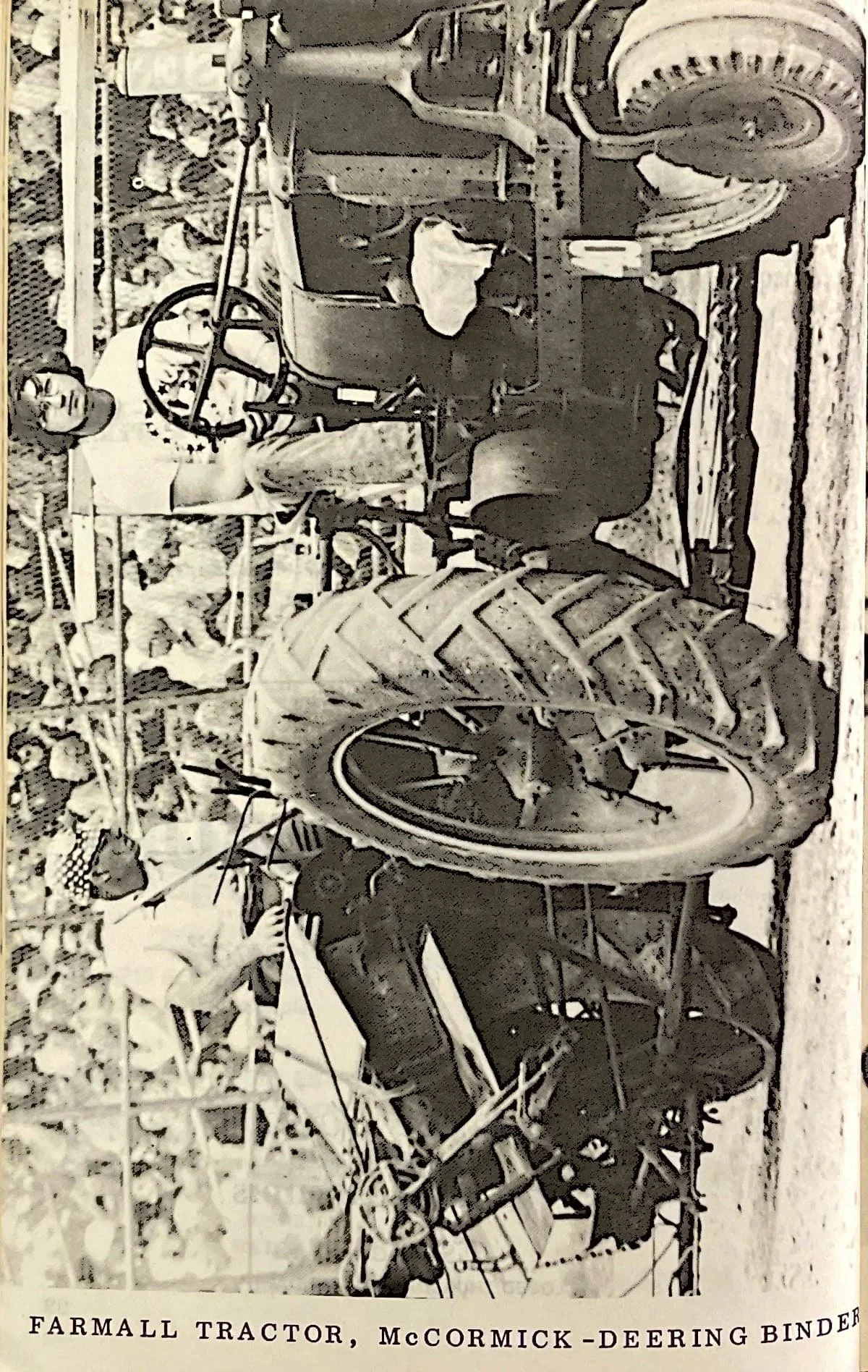

FARMALL TRACTOR, McCORMICK-DEERING BINDER

"FAULT" GAS ENGINE OWNED BY DICK BORMS, PEOTONE

OLD TIME WATER WAGON OWNED & RESTORED BY RUSS HOSSBACK AND FRED WILHELMI BOTH OF JOLIET, ILLINOIS

KNOWLES PRINTING LTD. COMPLETE PRINTING SERVICE. 1118 N. Raynor Ave. Joliet, Illinois. Telephone 727-1830. COMMERCIAL JOB PRINTING, CAMERA WORK, PLATE MAKING, LAYOUT & MAKEUP, LETTERHEADS, ENVELOPES, WEDDING INVITATIONS, OFFSET PRINTING, STATEMENTS, PROGRAMS, BOOKLETS, BUSINESS CARDS, RAFFLE TICKETS, HANDBILLS “Personal Service a Guarantee"